Samarium cobalt magnets, also known as samarium cobalt magnets, are an alloy composed of two basic elements: samarium and cobalt. SmCo magnets are permanent and rare earth magnets available in a variety of sizes, shapes, and more. Their strength is similar to that of neodymium magnets, but they have additional properties that give them an advantage, such as high heat resistance, and due to their advantages, the popularity of samarium cobalt magnets has greatly increased.

Samarium cobalt magnets belong to permanent magnets and are one of the most common materials in the high temperature magnetic material market. Under the normal temperature working environment, compared with NdFeB magnets, its magnetic properties are not as good as NdFeB magnets. However, when the working temperature is 150-180°C, its maximum energy product, coercive force, temperature stability and chemical stability are stronger than that of NdFeB permanent magnets. So what effect does temperature have on samarium cobalt magnets? Let's take you to understand how the temperature affects the samarium cobalt magnet.

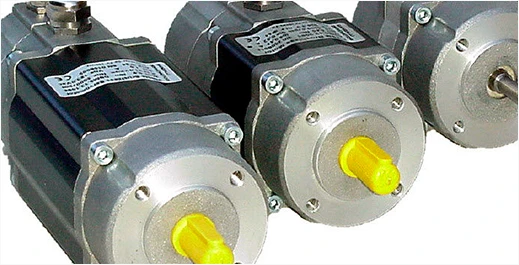

Samarium cobalt magnets are suitable for working in a higher working temperature environment, and the maximum working temperature of samarium cobalt magnets can reach 350°C. When the temperature exceeds 150°C, its magnetic performance can exceed that of NdFeB high-temperature magnets. For every 1°C increase in samarium cobalt temperature, the temperature coefficient of cobalt is about -0.04%, and if the maximum operating temperature is not exceeded, this loss will be fully compensated. Due to their thermal stability, samarium cobalt magnets are also ideal permanent magnets for aerospace, automotive, sensors, speakers, motors and military applications.

Samarium cobalt magnets not only excel at high temperatures, but also maintain their magnetic properties even below absolute zero (-237°C), making them popular for low temperature applications. Samarium cobalt magnets have many advantages that make them ideal for industrial applications. These benefits have contributed to the growing popularity of samarium cobalt magnets. In fact, samarium cobalt magnets may be more suitable than neodymium magnets in some situations. Despite the various advantages of samarium cobalt magnets, there are a few considerations you should keep in mind when considering samarium cobalt magnets for your business application. Magnets can be brittle and work best in applications that don't require direct impact. These magnets are sensitive to market price, but they are usually more expensive than some neodymium magnets. This is mainly due to the cost of producing cobalt and the fact that most magnets are produced overseas.

Due to the superior characteristics of samarium cobalt magnets, these magnets have a wide range of industrial applications. Magnets are often used in applications where magnetic strength and stability at high temperatures are critical. Some examples of industrial uses for samarium cobalt magnets include: electrical machines and motors, sensors, pump couplings, high temperature applications, food processing, prosthodontics, generators. Samarium cobalt magnets can withstand high temperature and low temperature. Temperature resistance is a characteristic of samarium cobalt magnets, but its high price makes it less widely used than neodymium iron boron.