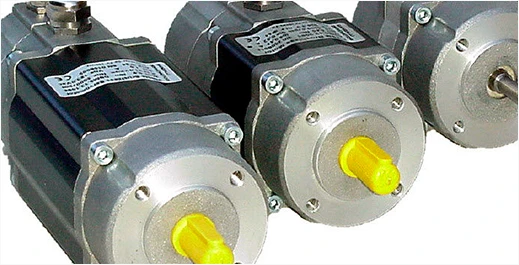

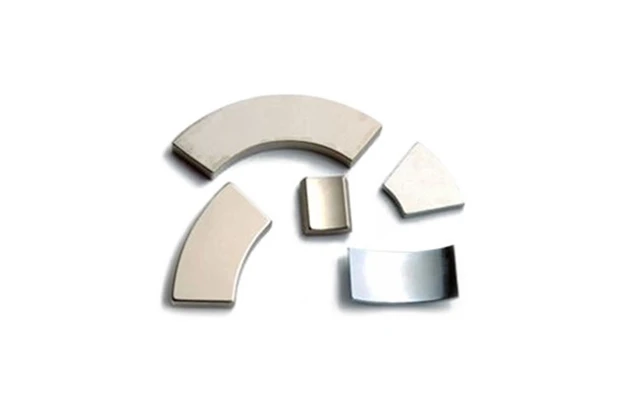

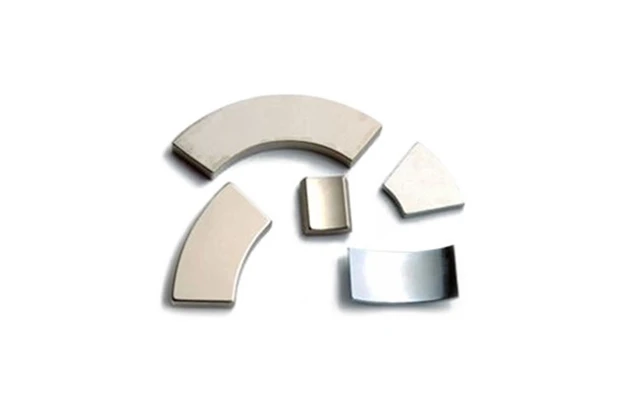

High Temperature Resistant Neodymium Arc/Curved Magnets, High Temperature Resistant Motor Magnets

Neodymium arc magnets are perfect for engineering and industrial applications that require precision and efficiency. These magnets have a unique curved shape and offer impressive magnetic strength, making them perfect for use in motors, generators, and sensors.

| Category | Arc Magnets |

| Material & Grade | NdFeB-35EH |

| Br | ≥11700Gs |

| HcB | ≥11Koe |

| HcJ | ≥30Koe |

| Tolerance | +/- 0.1 mm |

| Direction of magnetization | diametrically |

| Surface Treatment | Nickel-plated (Ni-Cu-Ni) |

| Max. working temperature | 200°C |

O-Grade: N35, N38, N40, N42, N45, N48, N50, N50;

M-Grade: 33M, 35M, 38M, 40M, 42M, 45M, N48M, 50M;

H-Grade: 35H, 38H, 40H, 42H, 45H, 48H;

SH-Grade: 35SH, 38SH, 40SH, 42SH, 45SH;

UH-Grade: 28UH, 30UH, 33UH, 35UH, 38UH, 40UH

EH-Grade: 28EH, 30EH, 33EH, 35EH, 38EH

AH-Grade: 28AH, 30AH, 33AH, 35AH

Nickel-Copper-Nickel (three layers coating), Zn, phosphatizing, Epoxy

N-Series ≤80°C; M-Series ≤100°C; H-Series ≤120°C; SH-Series ≤150°C; UH-Series ≤180°C; EH-Series ≤200°C; AH-Series ≤230°C;

Neodymium-iron-boron magnetic tile, also known neodymium arc/curved magnet, it is usually made of SH, UH and EH-grade materials (these grade are high temperature resistant) by wire cutting. These types of high temperature resistant curved/arc magnets are usually used in DC motors, rotors and stators. Galvanized, epoxy and nickel are often used for high temperature resistant neodymium arc/curved magnets. High temperature resistant neodymium arc/curved magnet belongs to custom magnet, and drawings need to be provided, but open mold production is not required.

Please fill the form to let us know your need. Our sales will get in touch with you ASAP.

1 FLOOR, NO.128 BUILDING-1 128#, JIJIN ROAD, XIAOGANG, BEILUN, NINGBO CITY, ZHEJIANG PROVINCE, CHINA