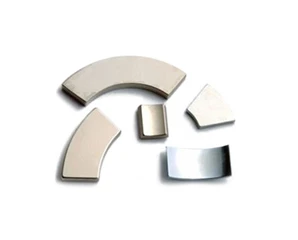

Rare Earth Powerful Neodymium Arc/Curved Magnets With Epoxy Coated

| Category | Arc Magnets |

| Material & Grade | NdFeB-N35EH |

| Br | ≥11700Gs |

| HcB | ≥11Koe |

| HcJ | ≥30Koe |

| Tolerance | +/- 0.1 mm |

| Direction of magnetization | Diametrically |

| Surface Treatment | Nickel-plated (Ni-Cu-Ni) |

| Max. working temperature | 200°C |

N-Grade: N35, N38, N40, N42, N45, N48, N50, N52 Arc Magnets;

M-Grade: 33M, 35M, 38M, 40M, 42M, 45M, N48M, 50M;

H-Grade: 35H, 38H, 40H, 42H, 45H, 48H;

SH-Grade: 35SH, 38SH, 40SH, 42SH, 45SH;

UH-Grade: 28UH, 30UH, 33UH, 35UH, 38UH, 40UH;

EH-Grade: 28EH, 30EH, 33EH, 35EH, 38EH;

AH-Grade: 28AH, 30AH, 33AH, 35AH;

N-Series ≤80°C; M-Series ≤100°C; H-Series ≤120°C; SH-Series ≤150°C; UH-Series ≤180°C; EH-Series ≤200°C; AH-Series ≤230°C;

Epoxy coating is one of the common coatings for curved neodymium (NdFeB) magnets. Our epoxy coating consists of metal electroplated layer (usually nickel + copper) and epoxy resin electrophoresis layer, that means our epoxy coated curved neodymium magnets have three-layer coating.

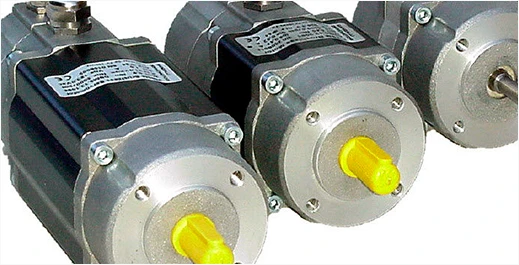

Application of epoxy coated neodymium magnetic tile: epoxy coated curved neodymium magnets (magnetic tiles) are mostly used in elevator, compressor and motor fields

Advantages of epoxy coating: high temperature resistance, salt spray resistance, thicker coating and many colors (the commonly used color is black).

Nickel-Copper-Nickel (three layers coating), Zn, phosphatizing, Epoxy

Please fill the form to let us know your need. Our sales will get in touch with you ASAP.

1 FLOOR, NO.128 BUILDING-1 128#, JIJIN ROAD, XIAOGANG, BEILUN, NINGBO CITY, ZHEJIANG PROVINCE, CHINA