The source said that a feasibility study report funded by the British government was released, which listed the steps that the UK must take to restart the production of rare earth permanent magnets.

In the 1990s, when British manufacturers found that they could not compete with Chinese enterprises, magnet production disappeared in Britain. However, with the huge growth of demand, the British government was eager to obtain sufficient magnet supply.

Last month, the UK government formulated a plan to achieve its "net-zero strategy" for carbon emissions, including spending £ 850 million ($1. 15 billion) to support the production activities of electric vehicles (EVS) and their supply chain.

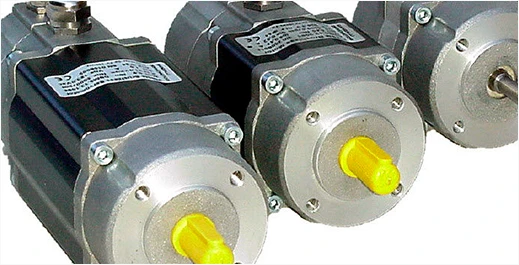

A magnet factory will be created to help the UK achieve its goal of banning the sale of new gasoline and diesel vehicles in 2030 and achieving "net zero-emission" of greenhouse gases by 2050. Sources who have read the forthcoming report say that the study outlines how to build such a plant by 2024 and eventually produce enough super magnet materials to supply the production of 1 million electric vehicles per year.

It is reported that 90% of electric vehicle motors need to use rare earth magnets made of neodymium, a rare earth element because they are widely regarded as the most effective way of power supply. Compared with electric vehicles using ordinary magnets, electric vehicles using these rare earth magnets consume less power, so they can drive longer when charged.

According to the European Union, by 2050, automobile manufacturers competing to increase the production capacity of electric vehicles and countries turning to wind energy will increase the demand for permanent magnets in Europe tenfold.