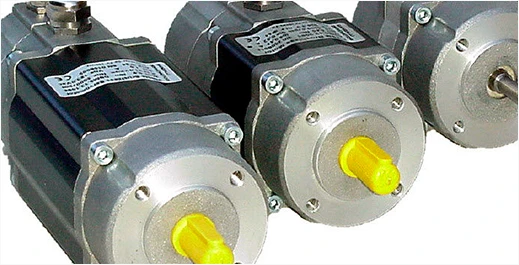

Rubber magnets are a kind of ferrite magnetic material, which is a flexible and elastic magnetic material that can be twisted and made into various shapes such as strips, rolls, sheets, blocks, rings, and complex shapes by extrusion, calendering, and injection molding processes. They are made by mixing bonded ferrite magnetic powder with synthetic rubber and other materials. Since their invention, rubber magnets have been widely used in various fields. Anisotropic rubber magnets can be used for motors and magnetic holding devices, while isotropic rubber magnets are suitable for advertising and educational tools.

Rubber magnets are flexible, elastic, and can be twisted. They can be produced into rolls, sheets, strips, blocks, rings, and various complex shapes through extrusion, calendering, injection molding, and other processes. They can also be coated with PVC film, copperplate paper, double-sided adhesive, UV oil, or printed and die-cut into various shapes.

The cost is very low.

Not easy to break.

The shape and size can be customized without the need for a mold fee.

It has elasticity and can be transported in rolls.

Can be self-adhesive and printed.

Multiple pole magnetization can be easily achieved.

Rubber magnets are composed of magnetic powder, chlorinated polyethylene (CPE), and other additives, and are made by extrusion and calendering. Rubber magnets can be isotropic or anisotropic, bendable, twistable, and rollable. They can be used without any further mechanical processing, can be trimmed to the desired size and shape, and can be coated with PVC, backed with adhesive, and coated with UV oil according to customer requirements. Its magnetic energy product ranges from 0.60 to 1.50MGOe. As an important branch of bonded magnets, the forming processes of rubber magnets include calendering and extrusion.

Production process: Ingredient mixing → Extrusion / calendering / injection molding → Processing → Magnetization → Inspection → Packaging.

Performance inspection: Appearance, dimensions, magnetic properties, polarity, hardness, density, tensile strength, aging resistance, winding performance.

Rubber magnets are widely used in refrigerators, message boards, fasteners for fixing objects to metal bodies for advertising, and magnetic sheets for toys, teaching instruments, switches, and sensors. They are mainly used in industries such as micro-spec motors, refrigerators, disinfection cabinets, cabinets, toys, stationery, and advertising.

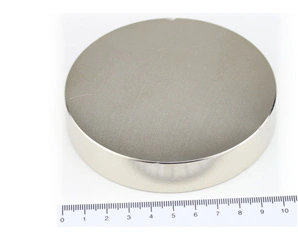

Beilun Mingke focuses on providing various permanent magnet materials (including NdFeB magnet, SmCo magnet, AlNiCo magnet, ceramic magnet, and flexible magnet) and pot magnets (mainly including NdFeB pot magnet and ferrite pot magnet). The magnetic parameters of all our permanent magnet materials are kept at the industry-leading level. We strictly control the tolerances of various permanent magnet materials according to industry standards. Our rare earth magnets are widely used in high-tech products because of their high quality. Our pot magnets have stronger magnetic force and better corrosion resistance, making them widely used in clamping, fishing, installation, and suspension.