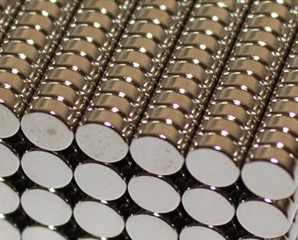

NdFeB magnets are widely used in electronic products, such as hard drives, mobile phones, headphones, and battery-powered tools. In order to avoid corrosion damage, it is necessary to protect the surface of the permanent magnet material during use, such as electroplating with gold, nickel, zinc, and tin, and spraying epoxy resin on the surface. NdFeB is divided into sintered NdFeB and bonded NdFeB. Bonded NdFeB has magnetism in all directions and is corrosion-resistant; while sintered NdFeB is easy to corrode, and the surface needs to be coated, generally galvanized, nickel, environmental protection zinc, environmental protection nickel, nickel copper nickel, environmental protection nickel copper nickel, etc. Sintered NdFeB is generally divided into axial magnetization and radial magnetization, which are determined according to the required working surface.

NdFeB, also known as NdFeB magnet, is a tetragonal crystal formed by neodymium, iron and boron. The magnetic energy product of this magnet is larger than that of the samarium cobalt magnet, and it was the material with the largest magnetic energy product in the world at that time. Later, Sumitomo Special Metals developed a successful powder metallurgy method. General Motors has successfully developed the rotary jet melting method, which can prepare NdFeB magnets. This magnet is the strongest permanent magnet available today and the most commonly used rare earth magnet.

Process flow: batching → smelting ingot making/stripping → powder making → pressing → sintering and tempering → magnetic testing → grinding → pin cutting → electroplating → finished product. Among them, the ingredients are the basis, and the sintering and tempering is the key.

NdFeB magnet blank production tools and performance testing tools: melting furnace, strip furnace, jaw crusher, jet mill, press molding machine, vacuum packaging machine, isostatic press, sintering furnace, heat treatment vacuum furnace, magnetic properties Tester, Gauss meter.

NdFeB magnet machining tools: centerless grinding, spheronizing machine, double-end grinding, flat grinding, slicer, double-sided grinding, wire cutting, table drill, special-shaped grinding, etc.

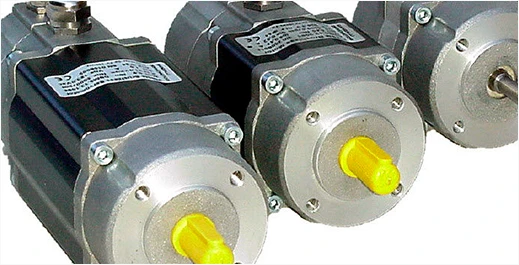

Sintered NdFeB permanent magnet materials have excellent magnetic properties and are widely used in electronics, electrical machinery, medical equipment, toys, packaging, hardware machinery, aerospace and other fields. The more common ones are permanent magnet motors, speakers, magnetic separators, Computer disk drives, magnetic resonance imaging equipment meters, etc.

The nano-chelate film without coating can be used in marine climate conditions for 20-30 years, and can be widely used in wind power generation. The surface adhesive force is more than 20Mpa, which can be widely used in permanent magnet high-speed motors, special motors, electric vehicle motors, UHV, high-voltage DC power supply systems, fast charging systems, aerospace and military industries.