In the dynamic world of magnets, rare earth magnets stand out for their exceptional strength and versatility. When faced with harsh environmental conditions, these magnets need an extra layer of defense. Enter plastic-coated rare earth magnets, the unsung heroes that not only preserve their magnetic prowess but also shield them from the challenges of harsh environments. In this blog, we'll explore the significance of plastic coating in rare earth magnets and how they thrive in conditions that would challenge other materials.

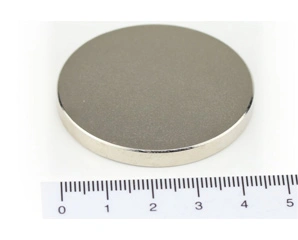

Rare earth magnets, including neodymium and samarium-cobalt magnets, boast unparalleled magnetic strength. Their ability to generate powerful magnetic fields has made them indispensable in various industries, from electronics to renewable energy.

However, the same magnetic properties that make rare earth magnets valuable can also render them susceptible to corrosion and damage in harsh environments. Moisture, chemicals, and abrasive elements can compromise their structural integrity over time.

Plastic coating serves as a protective shield for rare earth magnets, creating a barrier between the magnet and the external environment. This coating, typically made of materials like epoxy or polypropylene, acts as a defense mechanism against corrosive agents and physical wear.

Harsh environments often expose magnets to moisture, which can lead to corrosion. Plastic-coated rare earth magnets are designed to resist corrosion, ensuring their longevity and maintaining their magnetic strength even when faced with challenging weather conditions.

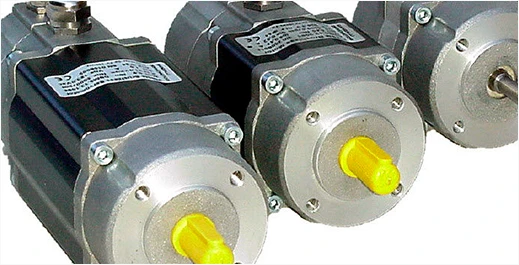

In the oil and gas industry, where exposure to corrosive substances is common, plastic-coated rare earth magnets find applications in various tools and equipment. Their resilience ensures reliable performance in drilling and exploration operations.

In marine environments, where saltwater poses a significant threat to metal components, plastic-coated rare earth magnets play a crucial role. They are employed in navigation systems, sensors, and underwater equipment, withstanding the corrosive effects of seawater.

Plastic coating not only protects rare earth magnets but also opens up new possibilities in design and application. The coating can be customized for color, allowing for aesthetic considerations in addition to functional benefits.

The protective layer provided by plastic coating significantly enhances the overall durability of rare earth magnets. This makes them suitable for long-term use in applications where other materials might succumb to environmental challenges.

Plastic-coated rare earth magnets are a testament to the intersection of strength and resilience. In harsh environments where other materials might falter, these magnets not only maintain their powerful magnetic properties but also emerge unscathed from corrosive conditions. Whether in oil and gas exploration, marine engineering, or other challenging industries, the power of protection offered by plastic-coated rare earth magnets ensures that they continue to attract success even in the harshest of environments.