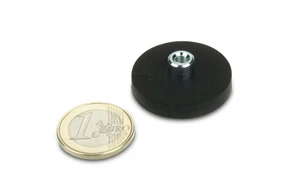

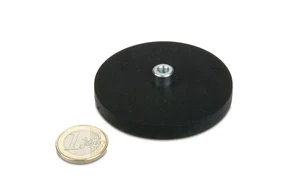

The rubber coated base (mounting, pot) magnets under this category are gummed with female threaded bushing. Threaded hook and eyebolt are accessories for these female threaded rubber coated mounting base pot magnets with threaded bushing/socket. The larger rubber coated magnetic system is multi-poles magnet, there are several magnets stuck to the iron plate on the magnetized surface.

Common size of rubber coated(rubberized)base magnets that with threaded bushing various from 12mm to 88mm in diameter, the size is bigger and the strength is stronger. Most of internal threaded rubber coated base magnet with threaded bushing are supplied in black color.

Items Code | D(mm) | H(mm) | L(mm) | d(mm) | M | Force(kg) | Weight(g) |

RCINS-D12 | 12 | 6 | 10.5 | 8 | M4 | 1 | 6 |

RCINS-D22 | 22 | 6 | 10.5 | 8 | M4/M6 | 6.5 | 13 |

RCINS-D31 | 31 | 6 | 10.5 | 8 | M4/M6 | 7.5 | 22 |

RCINS-D43 | 43 | 6 | 10.5 | 9 | M4/M6 | 8.5 | 33 |

RCINS-D66 | 66 | 8 | 12 | 12 | M5/M6/M8 | 18 | 105 |

RCINS-D88 | 88 | 8 | 13.5 | 15 | M6/M8/10 | 42 | 192 |

The female thread rubber coated base magnet with threaded bushing can be used as fridge magnetic hook.

The rubber coated mounting pot magnets with internal threaded bushing can be used for tool organizing.

Rubberized round base magnets with female threaded bushing are used for holding plastic pipe.

The largest and strongest rubber coated base pot magnets with internal threaded bushing are applicable to heavy duty hanging and lifting.

Please fill the form to let us know your need. Our sales will get in touch with you ASAP.

1 FLOOR, NO.128 BUILDING-1 128#, JIJIN ROAD, XIAOGANG, BEILUN, NINGBO CITY, ZHEJIANG PROVINCE, CHINA