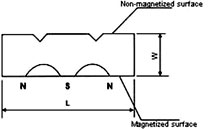

The strip magnet formed by the bonding of ferromagnetic powder and polymer is a MEANK flexible rubber magnetic strip. These high-energy MEANK rubber magnet strips will not break, and can resist demagnetization. The MEANK flexible rubber magnetic strips are magnetized with two or more magnetic poles along the length of the surface to form a concentrated strength on the surface of the rubber strip magnet. MEANK flexible rubber magnet strips are great for signage and labeling steel shelves, drawers, file cabinets, magnetic white boards, doors, trays, machinery, etc.

Flexible rubber magnetic (magnet) strips with groove are widely used in door sealing for refrigerator and bathroom

Flexible rubber magnetic (magnet) strips with groove are widely used in door sealing for refrigerator and bathroom

L | 8±0.15 | 9±0.15 | 9±0.15 | 9±0.15 | 9.8±0.15 | 10±0.15 | 10±0.15 |

W | 4±0.07 | 2±0.07 | 2.6±0.07 | 3±0.07 | 3.1±0.07 | 3±0.07 | 5±0.07 |

Br (Gs) | ≥650/≥720 | ≥560 | ≥620 | ≥680 | ≥680 | ≥680 | ≥650/≥720 |

Code | Br | Hcb | Hcj | (BH)max | Forming way | Size | ||

T | KA/m | KA/m | KJ/m3 | Max Length(m) | Max Width(mm) | Height(mm) | ||

RMS-1 | 0.13~0.18 | 80~115 | 100~160 | 4~6.4 | Extrusion | 100 | 400 | 0.4~1.1 |

RMS-2 | 0.18~0.22 | 100~140 | 120~190 | 6.4~8.0 | Extrusion | 2 | 930 | 0.6~3 |

Physical Features Of Extruded Rubber Magnetic Strip

Code | Tensile Strength (MPa) | Elongation Rate (%) | Hardness (SHA) | Temperature (℃) | Density (g/cm3) |

RMS-1 | 5~10 | 30~100 | 85~98 | -10~80 | 3.6~3.7 |

RMS-2 | 5~10 | 40~100 | 85~98 | -10~80 | 3.6~3.7 |

Surface treatment of flexible magnetic strips:

1. Flexible magnetic strips-smooth, plain brown, matte / gloss.

2. Flexible magnetic strips with 3M self-adhesive or white self-adhesive.

3. Flexible magnetic strips with white PVC (copper paper) or color PVC (copper paper), with / without printing.

Property Of Flexible Rubber Magnetic Strips:

1. Isotropic flexible rubber magnetic stripsl: with weak magnetism, used in refrigerators, printing, and promotion.

2. Anisotropic flexible rubber magnetic strips: with strong magnetism, use in micro-motors.

Plain Flexible Magnetic Strips

Plain Flexible Magnetic StripsNothing is attached on the surface of plain flexible magnetic strips.Plain magnetic strips are great for making lightweight projects,they are perfect items for home, school and office to make sign makers, crafts, hobbyists and DIY job.

Available Length: 15,20,30,60m Available Width: 0.25,0.5,0.75,1,2 inch

Adhesive Magnetic (Magnet) Strips

Adhesive Magnetic (Magnet) StripsThe magnetic strips are attached adhesive on one surface, they can be used on non-metal surface.Adhesive backed flexible magnetic(magnet) strips are used to make sign makers, crafts and DIY jobs at home,school or in office.

Available Sizes: 12.5 x 1.5, 12.7 x 1.5, 19 x 1.5, 25.4 x 1.5 mm with length of 15,20,30,60m (special size can be customized). Property Available: isotropic and anisotropic rubber magnet. Available Adhesive: Tessa, 3M,and other adhesive for options.

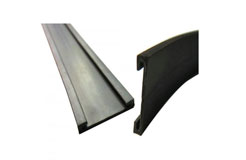

C-profile Rubber Magnet (Magnetic) Strips

C-profile Rubber Magnet (Magnetic) StripsSize Available: 10x1,15x1,20x1,25x1,30x1,40x1,50x1,more sizes can be customized based on needs. Length Available: 30 or 50 meters per roll,various length can be customized for special requirement. Magnetic Property: Isotropic Rubber Magnets. Magnetization: single side and multi-poles(only one surface has magnetism).

-strip-magnet-to-magnet-applications.jpg)

For fixing of posters and graphics in display systems, the magnet to magnet applications are better. Besides of Mag "A"/Mag"B", other types of self aligning magnetic systems can be customized on request.

Flat profile(adhesive backed) extruded magnetic strips that magnet to steel application is ideal magnetic system, which used where is no ferromagnetic surface, A standard application of magnet to steel strip system is to hold mosquito frames to wooden or aluminum window frame.

Please fill the form to let us know your need. Our sales will get in touch with you ASAP.

1 FLOOR, NO.128 BUILDING-1 128#, JIJIN ROAD, XIAOGANG, BEILUN, NINGBO CITY, ZHEJIANG PROVINCE, CHINA